고정 헤더 영역

상세 컨텐츠

본문

What we have. Gas turbine performance simulations?.

New concepts for seals and coatings?. Life assessment of gas turbine parts (e.g. Blades)?. Support in engine sustainment and procurement?.

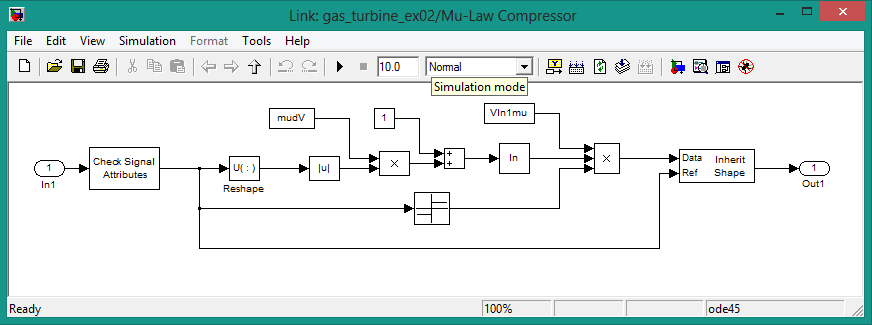

Gas Turbine Simulation Programming Software

High temperature materials (thermal barrier coatings, super alloys, CMC)?. Repair technology?Extensive experience with, and knowledge of, high temperature materials (super alloys, thermal barrier coatings, CMC), life assessment, seals and repair technology.We perform research for both aero and stationary gas turbine engines. For example we develop new concepts for seals and coatings, including testing in the NLR seal test rig and burner rig. We also explore the application of Laser Additive Manufacturing (LAM) technology for manufacturing and repair, and Ceramic Matrix Composites (CMC).For gas turbine performance simulation we developed the Gas turbine Simulation Program (GSP) in-house. GSP is under continuous development in close cooperation with the Delft University of Technology (TU Delft).

Gas Turbine Simulation Software

For GSP visit:NLR is a member of the Dutch Aero Engine Cluster (DAEC) and the Dutch Gas Turbine Association (DGTA).